The term PAT Testing is generally used to describe the procedure of examining the efficiency, safety, and security of electric home appliances and systems in the workplace. The term itself functions as a (tautological) acronym of Portable Appliance Screening, although the process is typically described as In-service Inspection & Screening of Electrical Tools.

Before checking out just how PAT testing is done, it deserves to consider the objective behind it and the requirements that drive it. The essential purpose is to ensure the safety of electric equipment. Still, to this end, it is likewise crucial that records are maintained of the security of private electric products and, following an evaluation, when they will require to comply with-up inspections.

Numerous laws call for the application of PAT testing. Still, the major piece of regulation is the Power at the workplace Regulations 1989, which demands that employers guarantee electric devices are preserved sufficiently to stop the danger. More particular standards on evaluating when and how often a home appliance needs screening are provided by both the Health & Safety Exec and the Establishment of Engineering and Modern technology.

Initial Checks

The first steps in making sure the safety and security of an electric home appliance ought to preferably be done by the users of that appliance, who should be triggered to carry out standard visual checks whenever they use it. Faults like torn or loosened wires can be determined (and corrected) at any phase by any individual without particular training and need to not, therefore, remain a risk until the next set up PAT test.

Before executing a specific rub test, a skilled tester should also do a visual check of the appliance to seek outside evidence that will certainly exist for the huge majority of faults. When a formal pictorial review is full, a PAT test should be done once more by a skilled individual, utilizing the appropriate testing tools (see listed below).

That carries out PAT Testing.

The actual PAT screening can be executed by anybody with adequate training deemed experienced. This might therefore comprise a participant of the team in the office who has received training such as a City & Guilds certification (although there is no one acknowledged qualification that testers call for), or an outside organization.

There are obvious benefits to both; making use of internal personnel may bring less costly work expenses as well as higher versatility; nonetheless, using professional PAT Evaluating firms would certainly get benefit from a greater degree of know-how – obtained via the experience of doing tests day-in-day-out – in addition to negating the requirement to purchase in the required testing tools independently. As rub testing is a job that relies, to a substantial degree, on the reasoning of the tester, the last alternative may ultimately be better.

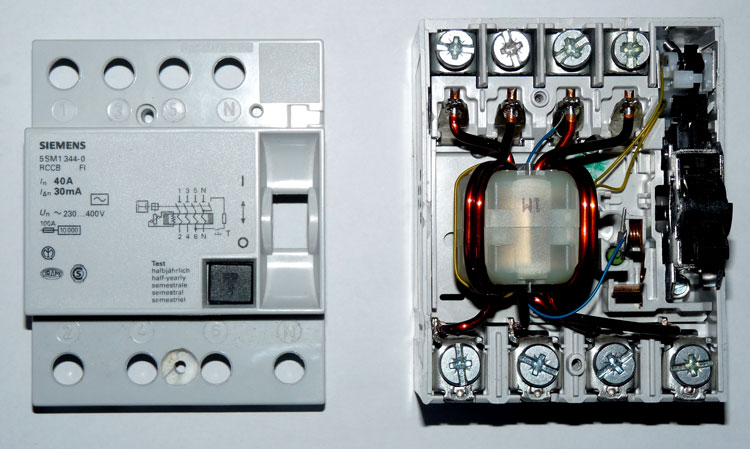

PAT Testing Devices

For those rub Testers that are more seasoned or highly educated, normally at expert RCD Testing firms, there are more advanced rub tools readily available which give a lot more detailed testing metrics and advanced functionality to manage those outcomes. For instance, testing devices can perform checks such as fuse, lead polarity and RCD examinations along with the basic functionality and afterwards screen and also videotape the more intricate analyses. Latterly, computerized PAT testers have permitted users to in fact save, analyze as well as contrast these results on the tool itself instead of moving them to an additional computer system for evaluation.